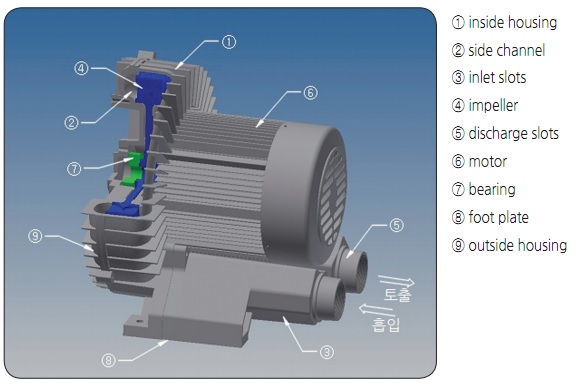

Structure And Name Of Main Parts

Ring Blower is a Blower which can alternatively use strong unlet and discharge pressure generated from ⑤Discharge slots. The gas flowing into ③ Inlet slots get increased pressure by centrifugal force of impeller,and while passing through ② Inside channel and being pressure by the housing,vortex of impeller wings generates high wind pressure. The blower is classified into single and double stage according to impeller structure.

Characteristics

○ Generate 7~8 times higher pressure compared to turbo blower

○ Always provide clean air as it does not use any oil

○ Easy to install and cost saving with low maintenance cost

Applications

○ Provide oxygen in septic tank,Waste water disposal plant,Fish farm,Etc

○ Textile machinery industry including auto,Weaving machine,Knit-ting machine,Spinning and weaving machine,Etc

○ Remove cutting scrap of machine tools such as press,Grinder,Etc

○ Packaging machine and facilities for return delivery

○ Food processing equipment for cutting transport

○ Medical equipment industy including dentel equipment,Hospital air bed,Etc

○ Plastic machinery indystry for plating liquid preservation and high quality plating

○ Industry plant machinery for transporting powder,Grain and forming air layer in hopper

○ Duist collector for air Ventilation and Discharge

Installation & pipe arrangement

1) Installation

○ Check “Appendix table 1″to figure out whether the blow has ade-quate specifications for usage type and conditions prior to instal-lation

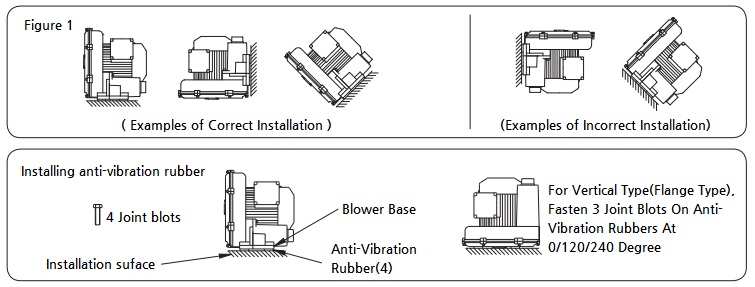

○ Install the product in horizontal orentation if possible.If una-voidable need to install it on inclined surface or in verticl orien-tation.Make sure that the impeller is facung downward as shown in “Figure 1″. At this instance,Insert anti-vibration rubber be-tween base and installation surface and fix the blower with blots in order to prevent vriation

2) Pipe Arrangement

○ For the installation,Check direction of Inlet and discharge holes and use pipe at one upper size than diameter of Discharge hole with consideration for Pressure loss due to friction

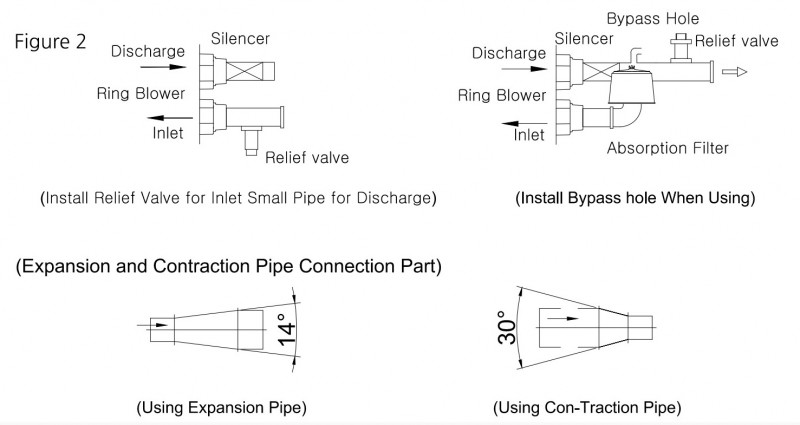

○ When using the product In higher pressure than rated value,Install and ues bypass valve as shown in figure2

○ When using reliefvalve,Check direction of valve operation

○ When using expansion or Contraction pipe,Make sure they are installed at shallow angle to reduce friction loss as shown in the figure above

Precaution in Use

1) Precation in Installation

○ Since the blower is high weighted,Be cautious about safety incident by avoiding any part of body including figure or foot being stuck while deliv-ering or installing the product

○ Install the blower indoor with goood ventilation and clean atmosphere adjust force during installation(As Maintaining horizontal or Vertical angle of piping gives direct influence if life span of the blower,Make sure blower opreates in normal condi-tions by using flexble hose)

○ When using PVC pipe,Use it after installing over 1mm of metal pipe in horizontal direction from discharge hole

○ Reduce noise and prevent absorption of foreing substance by using ab-sorption filter and discharge silencer

○ Check whether power connection matches with input voltage and solidly fasten the terminal block blots

○ Earth the blow to prevent safety incident caused by shor circuit

○ It is recommended to install 2 blowers(Paralle)in 1~2hour rotation for efficient operation of product

2) Precaution in use

○ Use blower under 40C of ambient temperature 80% of humidity

○ Due to attribute of ring blower,Note that the temperature of outer surface can increase up to 120C 30minutes after starting the product(Pay high attention on casing and discharge hole in particular)

○ Avoid using the product in a place with risk of explosion and combustion by corrosive liquid and gas including alkaline or acid substance

○ If cannot avoid using the product in a place with fine dust,Enhance absorption filter to minimize the amount of dust being absorbed

(In this case,Use enough size of filter and frequently remove foreign substance from the filter to prevent overload operation of the bloer)

○ The life span of bearing is approx.20,000hours in normal operation but check blower and replace bearing If there is noise or overheat bearing and grease in the bearing are different from general product.Contact out technicl team when replacing them

○ Since oil seal,Noise reduction material,and gasket consumables,It needs to replace them when refilling grease or replacing bearing

Precaution in Use

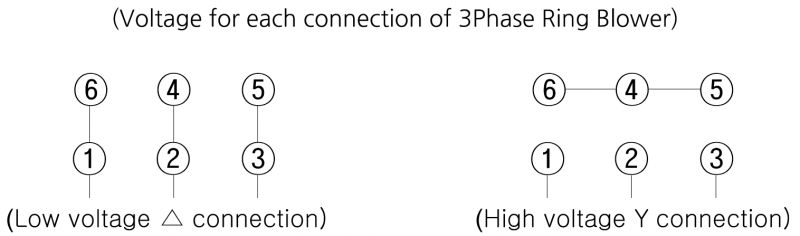

| Type | Low Voltage △ Connection | High Voltage Y Connection |

|---|---|---|

| 3Phase 1 Stage Ring Blower | 220V | 380V |

| 3Phase 2 Stage Ring Blower |

Unit of Pressure

| PSI | atm | ftH₂O | in.H₂O | Kgf/cm² | mAq | in.Hg | mmHg | cmHg | bar | mbar | kpa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.068 | 2.310 | 27.720 | 0.07 | 0.704 | 2.043 | 51.884 | 5.188 | 0.067 | 63.947 | 6.895 |

| 14.696 | 1 | 33.659 | 407.513 | 1.033 | 10.351 | 30.019 | 762.48 | 76.284 | 1.1013 | 10.3 | 101.32 |

| 0.433 | 0.0293 | 1 | 12.00 | 0.03 | 0.305 | 0.884 | 22.452 | 2.245 | 0.03 | 29.837 | 3.684 |

| 0.036 | 0.0025 | 0.833 | 1 | 0.0025 | 0.025 | 0.074 | 1.871 | 0.187 | 0.0025 | 2.486 | 0.249 |

| 14.233 | 0.968 | 32.867 | 384.408 | 1 | 10.018 | 29.054 | 737.959 | 73.796 | 0.981 | 980.882 | 98.066 |

| 1.422 | 0.097 | 3.287 | 39.37 | 0.099 | 1 | 2.905 | 73.796 | 7.379 | 0.098 | 98.066 | 9.807 |

| 0.489 | 0.0033 | 1.131 | 13.575 | 0.034 | 0.345 | 1 | 25.4 | 2.54 | 0.034 | 33.753 | 3.376 |

| 0.019 | 0.0013 | 0.045 | 0.534 | 0.0014 | 0.136 | 0.039 | 1 | 0.1 | 0.001 | 1.329 | 0.133 |

| 0.193 | 0.0131 | 0.455 | 5.34 | 0.014 | 0.135 | 0.393 | 10 | 1 | 0.0133 | 13.29 | 1.328 |

| 14.509 | 0.927 | 30.514 | 402.164 | 1.02 | 10.211 | 20.625 | 758.67 | 75.247 | 1 | 1000 | 100 |

| 0.014 | 0.0009 | 0.008 | 0.402 | 1.001 | 0.0152 | 0.029 | 0.752 | 0.075 | 0.001 | 1 | 0.1 |

| 0.145 | 0.0096 | 0.335 | 4.021 | 0.01 | 0.1020 | 0.296 | 7.525 | 0.75 | 0.01 | 10.0 | 1 |